EIT RawMaterials Hub - Regional Center Southern Italy

Download details

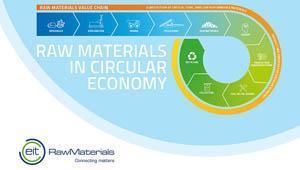

Why EIT RawMaterials and Circular Economy?

The EU is home to world leaders in manufacturing, game changing innovative technologies and an entrepreneurial infrastructure that can boost

the transition to a resource-efficient and sustainable society as envisioned in the EU 2020 agenda. A sustainable supply of raw materials is vital,

but the EU is highly dependent on imports of raw materials that are crucial for both this transition and for Europe’s industrial activity.

In particular, supplies of a range of ores, metals and rubber are vulnerable. A circular economy could increase the efficiency of primary resource

consumption both across Europe and the world. By conserving materials embodied in high-value products, or returning waste to the economy as

high-quality secondary raw materials, a circular economy would reduce the demand for primary raw materials. In turn, this would help to reduce

Europe's dependence on imports, reducing pressure on the procurement chains for many industrial sectors from the price volatility of international

commodity markets and supply uncertainty due to scarcity and/or geopolitical factors.

The challenge for EIT RawMaterials is thus to fully utilise the potential of industrial symbiosis by applying a systemic perspective and revitalising

the human capital in the raw materials sector through two strategic objectives:

DESIGNING SOLUTIONS: At the concept stage, many key decisions are made which have significant and lasting consequences from a raw materials

perspective. In terms of system design in the future, a systemic approach to materials innovation, products, product-service systems, processes and

wider systems across the whole lifecycle is essential. EIT RawMaterials will use powerful multi-scale modelling and decision-making support tools

based on big data to offer new opportunities for designing smarter solutions.

CLOSING MATERIAL LOOPS: A radical shift is required: from linear to circular thinking. End-of-life products must be considered as resources for

another cycle, while losses and stocks of unused materials must be minimised all along the value chain. In addition, interactions between materials

must be taken into account in order to define the best circular solution from a systemic standpoint. Awareness of the benefits of closing material

loops must be raised amongst students, industry and society.